Description

Automatic Assembling Welding Straightening H Beam Production Line, High Quality H Beam Production Line#

This machine is designed according to special character of vessel welding,its mainly consist of Gantry frame,slide structure,welding gun tracking device,Flux recovery system,electrical control system and Submerged welding machine.

Technical parameters

● Web beam height: | 200—1800mm |

● Web beam thickness: | 6—32mm |

● Flange beam width: | 200—800mm |

● Flange beam thickness: | 6—40mm |

● H beam length: | 4000—15000mm |

● Assembling speed: | 0.5—8m/min |

● Input roll: | 3000mm×3 |

● Output roll: | 3000mm×3 |

● Adjust method: | AC converter |

● Power: | 9 Kw |

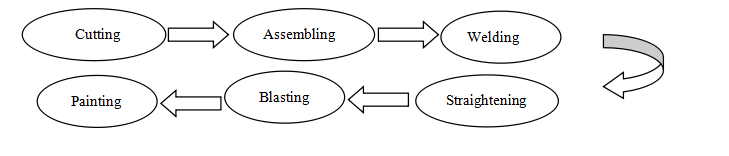

Process Flow

Supply scope.

Assembly machine :main machine,gantry bracket,flange synchrony clamping system,main transmit motor and reducer etc ● Input rolls :drive and idler rolls 3000mm*3 sets and 2 sets bar system ● Output rolls:drive and idler rolls 3000mm*3 sets ● Hydraulic system :oil pumping stations,high pressure rubber tube and 8 hydraulic pots etc ● Electrical system :electric cabinet,Electric control panel ,AC inverter(Schneider) ● Automatic spot welding system:2 sets CO2 NB-350A welding sources etc. ● Spare parts :3 buttons,2 HH54PDC24V relay, three 4A and 6A fusible core ● Instruction book(including electrical principle diagram,Hydraulic pump principle diagram,easy abrasion list etc) ● Inverter instruction book ,Hydraulic pump instruction book,PLC program instruction book ● qualified certificate,shipping list,pedestal diagram

Reviews

There are no reviews yet.